We Care Your Concerns

Price

Elevate your brass valve business's profitability and competitive position with our targeted solutions. Our strategic initiatives are meticulously designed to prioritize cost-effectiveness:

1. Optimized Material Sourcing: Gain cost advantages by streamlining the procurement of brass materials and spare parts from trusted local suppliers. This strategic approach guarantees favorable pricing, reinforcing your competitive positioning within the industry.

2. Efficiency Through Advanced Machinery: Increase production capabilities with our purpose-built high-efficiency machines and equipment for brass valve manufacturing. This technological upgrade not only elevates output but also solidifies your business's role as a key player in the market.

3. Precision in Production Process: Mitigate costs linked to defects through meticulous control over the brass valve production process. Our unwavering commitment to stringent quality control not only reduces expenses linked to error correction but also enhances the reliability of each valve produced.

Quality

Ensure the foundation of product safety and a stellar market reputation with our commitment to reliable quality in brass valve manufacturing. Discover our solutions designed to fortify product integrity:

1. Stringent Production Process Checks: Our production processes undergo meticulous quality checks by dedicated QC workers. Traceable records are maintained, ensuring transparency and accountability in maintaining quality standards.

2. Defect Identification Before Trimming: Each brass valve body undergoes thorough inspection to identify and address defects before the trimming process. This proactive approach guarantees that only high-quality components proceed to the next production phase.

3. Comprehensive Leakage Tightness Test:

Prioritize safety with a 100% leakage tightness test for every brass valve. This rigorous examination guarantees that each valve meets stringent quality standards, preventing potential issues in real-world applications.

Delivery

Accelerate your goods stock turnover and optimize cash flow with our solutions designed for swift delivery in the brass valve industry:

1. Streamlined Supply Chain: Optimize your material and spare part supply chain to significantly reduce lead times. Our strategic approach ensures a more efficient procurement process, minimizing delays in production.

2. Automatic Multi-Axis Machineries: Utilize cutting-edge automatic multi-axis machineries capable of machining valves in seconds. This technological advancement enhances production speed, allowing for quicker turnaround times without compromising quality.

3. Skilled Workforce Efficiency:

Employ a highly skilled workforce trained for efficiency. Our dedicated workers contribute to streamlined production processes, ensuring that tasks are executed promptly and with precision.

Aftersales

Experience worry-free operations with our commitment to excellent aftersales service, liberating you from warranty and technical concerns in the brass valve industry. Explore our comprehensive solutions:

1. Five-Year Quality Warranty: All our brass valves are backed by an extended five-year quality warranty, showcasing our confidence in their durability and reliability. This extended coverage provides you with an extended period of assurance and peace of mind.

2. Readily Available Spare Parts: We provide readily available spare parts and components for replacements across our entire range of brass valves. This ensures a quick resolution in the rare event of component issues, minimizing downtime for your systems.

3. Responsive Sales Team:

Our dedicated sales team is always at your service, ensuring prompt and effective communication. Whether you have inquiries, concerns, or require assistance, our team is ready to provide the support you need.

We Care Quality Control

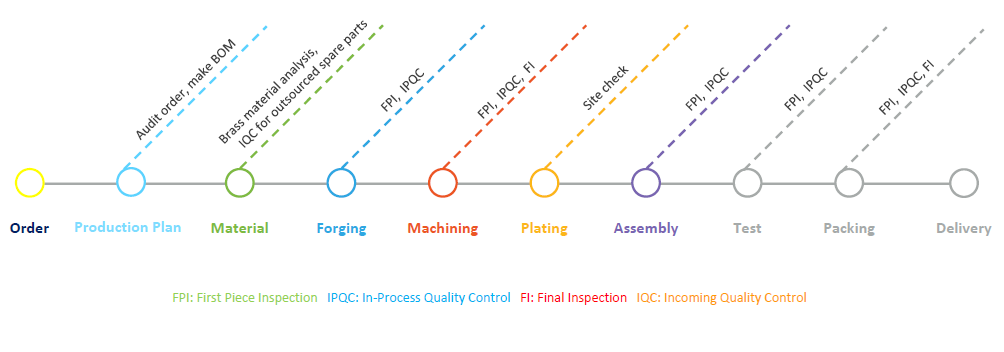

At the core of our unwavering commitment to excellence is a robust and comprehensive quality control system that meticulously oversees every facet of the brass valve production process, from the initial production plan to the final delivery. This meticulous approach is designed to ensure that each brass valve, bearing our name, adheres to the highest standards of quality, precision, and reliability.

First Piece Inspection (FPI): The journey begins with our First Piece Inspection, where our diligent Quality Control (QC) team meticulously scrutinizes the initial brass valve before mass production commences. This crucial step establishes a benchmark for the entire production run, setting stringent criteria that subsequent units must meet. Any deviation is promptly addressed to maintain the uncompromising quality we promise in every brass valve.

In-Process Quality Control (IPQC):As the production line gains momentum, our QC team conducts random checks through the In-Process Quality Control phase. These checks, strategically implemented during mass production, ensure that every brass valve aligns with our precise specifications. This real-time assessment is pivotal in identifying and rectifying any deviations promptly, guaranteeing consistency across the entire production batch.

Final Inspection (FI):Before our brass valves embark on their journey to customers, a meticulous Final Inspection is conducted. Every finished brass valve undergoes a comprehensive check to verify that it meets our unwavering quality standards. This exhaustive examination covers various parameters, including functionality, durability, and adherence to design specifications. Only when a brass valve clears this final hurdle is it deemed ready for delivery.

Incoming Quality Control (IQC):Ensuring quality isn't confined to the manufacturing floor—it begins with the materials and components we source. Our Incoming Quality Control is a proactive measure, where our QC team rigorously inspects outsourced materials and spare parts before they become integral to the production process. This meticulous scrutiny at the outset ensures that the raw materials meet our exacting standards, establishing a robust foundation for the entire production process of brass valves.

This fourfold quality control framework is not just a procedural checklist; it embodies our unwavering commitment to delivering brass valves that stand out in terms of precision, durability, and reliability. Our customers can rest assured that each brass valve leaving our facility has undergone rigorous scrutiny, reflecting our dedication to providing products that not only meet industry expectations but exceed them.

We Care Brass Valve Insection

Step inside our state-of-the-art test laboratory, the beating heart of our brass valve manufacturing excellence. Armed with cutting-edge devices like the material spectrometer analyzer, flow rate tester, torque tester, body resistance tester, endurance tester, and high-low temperature tester, this facility ensures our brass valves meet and exceed the highest industry standards.

The material spectrometer analyzer scrutinizes the composition of brass, guaranteeing that our valves are crafted with precision and durability. Our flow rate tester meticulously assesses performance under various flow conditions, ensuring optimal functionality. Torque testing ensures that our valves operate with the perfect blend of strength and precision.

The body resistance tester evaluates structural integrity, subjecting our valves to rigorous testing for longevity and reliability. Endurance testing simulates real-world conditions, assuring flawless performance in demanding situations. The high-low temperature tester adds the final touch, ensuring our brass valves maintain structural integrity across diverse thermal environments.

Beyond quality control, our laboratory serves as an innovation hub, driving new product development. Through material analysis and type tests, we constantly refine and push the boundaries of our brass valve solutions. This commitment to excellence positions our products at the forefront of performance, durability, and reliability across various applications.

We Care Brass Valve Production

As a leading brass valve manufacturer, we source premium raw materials such as HPb57-3, CW617N, and CW602N(DZR), laying the foundation for exceptional products. Our brass bars, like a harmonious symphony, showcase excellence in engineering cornerstones, inspiring creativity for robust structures or intricate craftsmanship. Choose our bars to unlock boundless possibilities and shape the beauty of brass in your projects.

Precision and craftsmanship define our brass valve bars, tailor-made to your unique specifications. Each bar undergoes meticulous cutting and a transformative heating process within a controlled temperature range of 650~825℃. This ensures optimal malleability, turning every piece into functional art that resonates with your vision. As a brass valve manufacturer committed to detail, we invite you to embrace the warmth of our craft, where every cut and flame brings your custom order to life.

Experience the beginning of brass valve excellence as heated brass bars undergo precise forging using advanced machines, this process yields semi-finished rough brass valve bodies—a testament to our commitment to precision craftsmanship. These components, shaped with cutting-edge technology, lay the foundation for the durability and performance that define our final brass valves. Each semi-finished piece surpasses industry standards, reflecting our dedication to delivering reliable and superior-quality products.

Crafting perfection is our hallmark as we refine rough brass valve bodies with precision and care. Trimmed and sculpted to their functional essence, these bodies surpass expectations. This transformative process, more than just trimming, orchestrates a symphony of cuts, leaving streamlined and purposeful valve forms ready to play a crucial role in your systems.

Witness the precision dance of our rough brass valve bodies undergoing a cleansing ritual. Guided by sanding machines, this process isn't just about aesthetics; it's a commitment to the purity of function and reliability. As a responsible brass valve manufacturer, we ensure that every valve body not only emerges clean but stands ready to perform flawlessly.

Delve into precision engineering as our CNC (Computer Numerical Control) machinery sculpts rough brass valve bodies. This advanced technology, orchestrating intricate movements, etches threads and defines dimensions with unparalleled accuracy. Our CNC-machined valve bodies stand as a testament to cutting-edge technology, promising reliability and performance in every thread and dimension.

Achieving a flawless finish is paramount as our machined brass valve bodies undergo nickel or chrome plating. While this enhancement is entrusted to an outsourced partner, it aligns with our commitment to environmental protection. Outsourcing ensures compliance with stringent environmental standards, reflecting our dedication not only to product excellence but also sustainable and responsible manufacturing.

In the final act of craftsmanship, meticulously crafted spare parts harmonize to form finished brass valve. Assembled with care, each component transforms into a cohesive and functional whole. Our meticulous packaging process ensures that from our facility to yours, each finished brass valve arrives with the same precision and care that went into its creation.

Celebrate the culmination of quality as our brass valve undergo a final finished goods quality inspection. Packed securely and accompanied by a certificate of quality, each valve symbolizes precision craftsmanship and reliability. As they leave our facility, these brass valve embody not just a product but a commitment to delivering solutions that inspire confidence in your systems. We look forward to our valves playing a crucial role, epitomizing quality and durability in your applications.

Contact Us Now

Enter your inquiry details, we will response within 24 hours.

Name can't be empty

E-mail can't be empty

Company can't be empty

Phone can't be empty

Phone

Products can't be empty

Products you want

Message can't be empty

Verification code error

Clear